Last Updated on 04/28/2019 by Mark Beckenbach

If you’ve been eagerly waiting for updates on the ONE INSTANT Peel Apart Film, you’ll want to keep your eyes peeled for this!

Anyone who has backed the ONE INSTANT Kickstarter project and been keeping tabs on the updates must be brimming with excitement now. They’ve dropped the latest on the production prototypes so far. It’s a success, and as they say, the devil is in the details! It’s amazing to see them so close to finally “hacking” the peel-apart instant film system, and they have the “latest (and greatest) tests” to prove it!

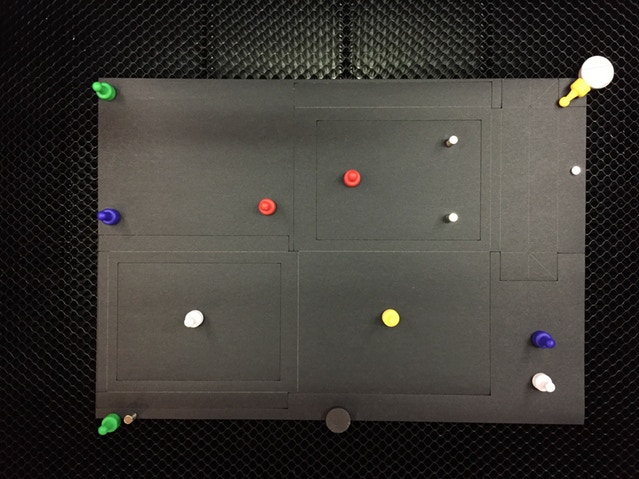

In the most recent progress report on Kickstarter, we get a glimpse of the design for the final production model based on the original proof-of-concept prototypes by Reanimated Film. This is what we saw in the campaign video. We’re told that there are about eight distinct parts, and each has to be made of different paper or synthetic materials. Their dimensions and form also have to be continuously improved and tweaked. Change one of these components and you have to do the same with another. All these parts must be put together with around 14 points of adhesion, each having its own specific role and position.

“Not only do we need to design a system that functions consistently in the hands of the end-user, but also something that can be assembled relatively easily and economically,” they say on the task at hand. “Unfortunately, the former desideratum seems to always complicate the latter! But alas, we’re going to make a great product no matter how much sweat and blood it takes.”

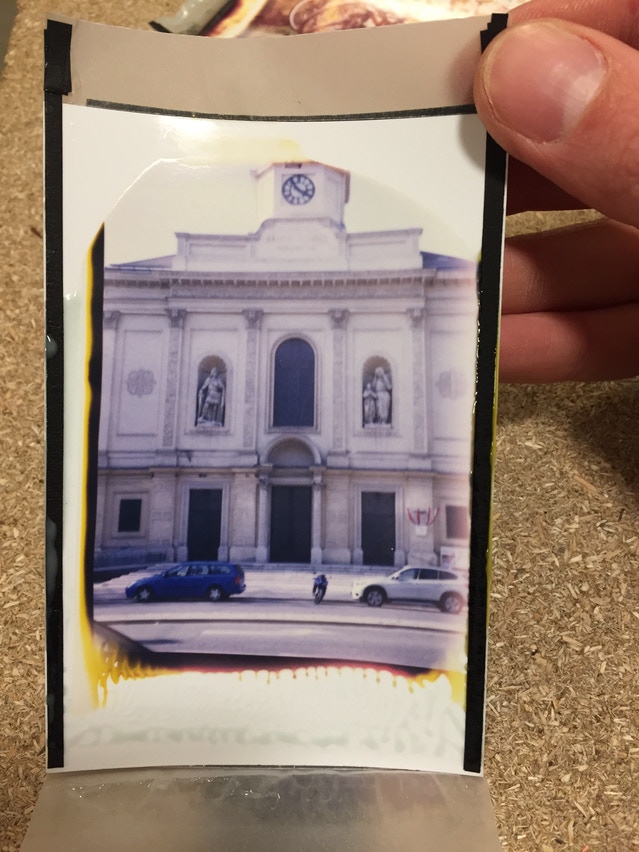

We also get a preview of the laser-cut paper parts and some test shots showing a few issues they’re currently sorting out. Among these are the mottled appearance on the print, and a mechanical malfunction that causes poor contact between the negative and the print.

To solve the former, they need a precise “rail-thickness” or the thickness of the black strips of tape along the sides of the print. This will provide the right gap for the rollers and apply the right amount of developing chemicals between the negative and the print. “Too thin and artifacts like this appear. Too thick and you are left with ‘goo stick’, where processing chemistry remains stuck to the print and not on the negative where it belongs.”

As for the mechanical issue, they had assistance from the 20X24” Studio to test a wide range of pod weights for finding “the sweet spot”. They also still need to figure out the right amount of chemical to get complete coverage for the image, and no more than that or else it will spill into the camera. With this, they now have an idea how to get complete chemistry coverage on the print, with most, if not all of the excess chemicals collecting neatly in the “goo trap”.

“The image of the potted plants (cover image) represents the best test to date. Complete coverage, excellent image quality, lowest in-camera mess. This is our goal.”

It’s all so exciting, and I’m sure peel-apart fans out there now have their hopes up. We all eagerly wait with you for the next update!

Photos from ONE INSTANT on Kickstarter