In all technical fields, digital imaging has won whatever was left of the film vs. digital debate— artistic qualities aside. Contemporary digital sensors are simply more precise, detailed, and flexible than film could ever hope to be. As early as the 1980s, the United States and its various corporate suppliers could already see the possibilities in digital sensors. They were hard at work researching alternative optical capture techniques that could supplant analog capture, especially in intelligence-gathering activities. The various surveillance bureaus of the United States had many of the same frustrations with film as current photographers; film is bulky, fickle, and time-consuming to process.

More about military history in photography can be read in our declassified series.

Commercial 35mm cartridges are reasonably compact and tolerable for use in land-based surveillance but wholly inadequate for aerial or stratospheric surveillance, which relied primarily on satellites whose optics were often measured in inches rather than millimeters. Aerial surveillance activities commonly employed 9-inch roll film, which captured a 9 by 9-inch square exposure whose area was slightly over 60 times larger than the standard area of 35mm film. Modern large format cameras frequently use sheet film in dimensions of (almost) 4 by 5 inches, and the whole camera system is many times larger and more cumbersome than a 35mm camera, and even still only exposes one frame at a time. Unlike still photography, though, lensing contributed much less to the overall bulk of the system than the vast apparatus required to automate the surveillance system. The most significant portion of a 9-inch roll film surveillance system was dedicated to the mechanisms needed to store, transport, and store the film in nothing less than complete darkness until it could be retrieved and processed correctly in special facilities awaiting eventual interpretation and analysis.

In addition to being light-tight, imaging systems used in aerial and stratospheric surveillance had to be hardened against weather (or vacuum) conditions, and preparing an apparatus that could reliably shoot and store images irrespective of high-G, low-G, and high-vibration conditions added significantly to development and deployment challenges. Further, film faces inherent delays and reproducibility problems associated with handling and development.

If the challenges of handling the film weren’t enough, the extremes of a high altitude ultra-long distance capture introduced problems all of its own. Different atmospheric and temperature conditions impact the film’s sensitivity and cause shrinkage and expansion of the substrate, affecting scale and geographic accuracy. Atmospheric anomalies and the angle of the satellite relative to the earth also necessitated a variety of films for a considerable number of conditions and targets, targeting different light spectrums with varying sizes of grain and sensitivity for all types of conditions.

In light of these challenges, electro-optical (digital) imaging offered a promising possibility, most notably in ameliorating delay from exposure to image viewing, but in the 80s, CMOS sensors weren’t yet highly developed, and the Bayer filter had only been recently invented and wasn’t yet in real use. Despite the downsides of film in practical deployment, in the 1980s, film still significantly outperformed digital imaging in one key area: resolution. Digital sensors simply lacked the resolution to capture any meaningfully resolved image from miles above the subject. The initial challenge to be solved was increasing resolution. As many professionals remember, the resolution was a challenge in early digital reproduction photography, and rather than relying on a complex polygonal sensor, early professionals often relied on scan backs. These backs worked like a document scanner, moving forward across the subject to draw the shape of a larger sensor.

Professionals will also remember that scan backs also require absolutely still subjects to make a sharp exposure. A traditional scan back simply wouldn’t work for deployment on a moving platform, but given the state of silicon sensors, this would be the only possible option.

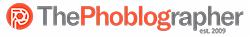

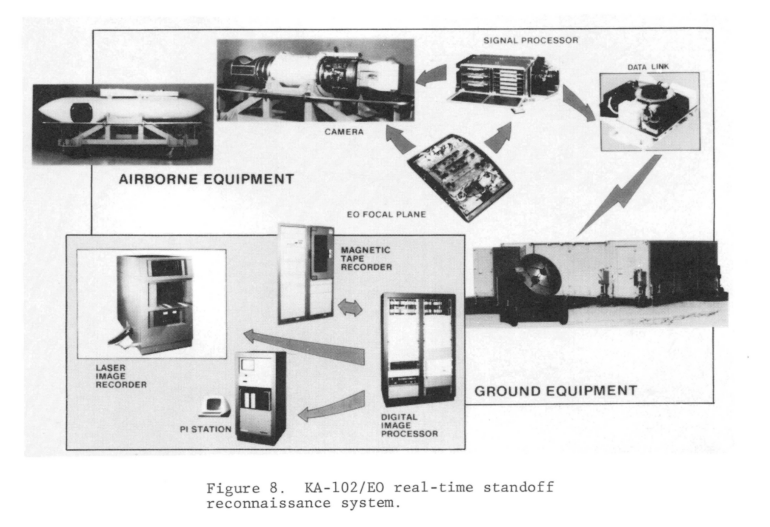

To help resolve these limitations, the government contracted the now legendary firm Itek to develop a new CCD sensor technology that could overcome these challenges. The CCD sensors developed and produced by Itek differed significantly from the Bayer CCD or CMOS sensors today and resembled a scan back sensor much more closely. Rather than being a rectangular sensor with a color filter array, the Itek sensors were long and thin, comprising a few pixels along their length and many more along the width and designed to capture the subject as it moved beneath the scanner, in contrast to a scan back which moves relative to the subject. This technology is referred to as Time Delay Integration (TDI) and involves timing the pixel exposure readout with the movement of an object underexposure. The fundamental (but oversimplified) way these sensors work is to read the light reflected from the object in all the different pixels along the path it moves. Instead of one section of the object being exposed on one pixel for 10 seconds, it might be exposed along 10 pixels for 10 seconds as it travels relative to the sensor along the path of those 10 pixels. The 10 different pixels track the object’s movement and add the sensor data from various pixels to reconstruct the scene.

Mounting film or a more typical sensor on a moving platform would normally have been a disadvantage because the relative movement of the object being exposed would have introduced blur. In the case of the Itek TDI CCD sensor, the relative movement of the object is an integral part of the exposure process, turning what, under normal circumstances, was a disadvantage into an advantage. This meant that when properly calibrated, the sensor could control the movement of the platform and of the subjects under surveillance. A positive secondary benefit of linearly arranged CCD is that they introduce a less detrimental distortion compared to imaging sensors arranged in a plane. Unlike a planar arrangement, there isn’t the same kind of corner vignetting that most consumers are accustomed to. Instead there is a limited falloff in the top and bottom, which would be similar to a slightly bowed piece of paper.

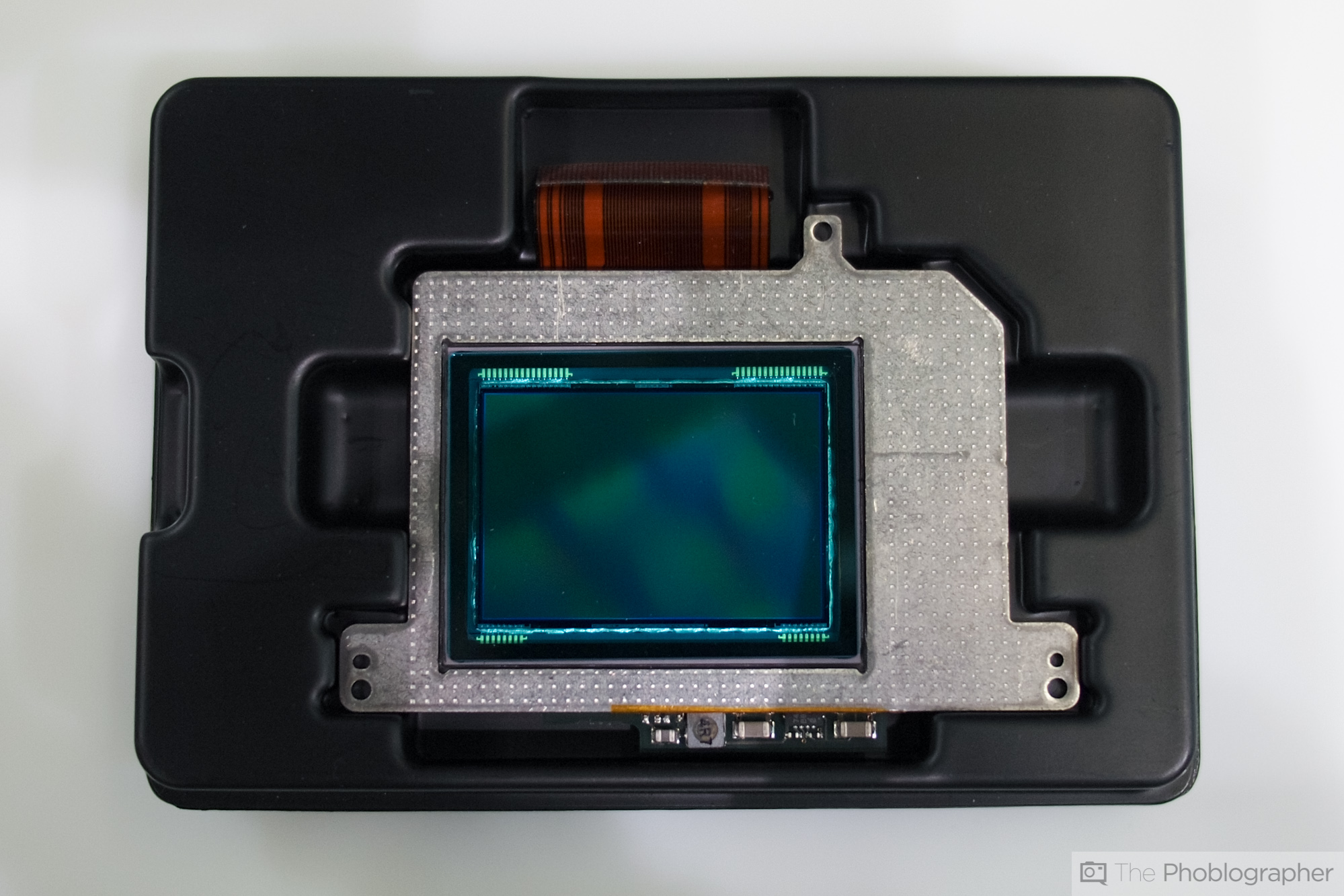

In addition to minimizing the system size, digital sensors simplified the entire production and processing chain. The vastness of the Eastman Kodak facilities for producing various imaging technologies was a testament to the technical marvel of film and, more than anything, a product of the need for specialization inherent in the production of every film stock. In addition to Kodak’s vast historical catalog of emulsions, it also produced special order films in batches, on demand. Each stock required research, development, production, prototyping, storage, and transport. The film production process was both time-consuming and costly, but ultimately most frustrated by the variability of the natural environment on deployment. One of the critical advantages Itek purported their CCD technology to have was only tangential to the production of the physical sensor: prototyping and image processing. Itek’s sensor development occurred in a multidisciplinary, collocated research facility where every stage of the imaging process could be tested for and provide immediate feedback. This process began with the ability to simulate the variety of conditions that the imaging system would be deployed in. Rather than needing to take images with actual film, develop that film, research a new coating or emulsion, produce a test batch, and repeat, the imaging system could be placed in various simulated environmental conditions and immediately interrogated for improvements. After device testing, the captured data would be passed to the research laboratory’s image recording, image enhancement, and real-time data processing sections. Digital photographers will be familiar with the malleability of digital raw data, and this was no different, albeit to a lesser extent involving far less data. In addition to being able to test the capture device itself, the remainder of the processing pipeline could also be optimized for function in various conditions in a way that wasn’t possible with film.

Where desirable, it was possible to (near) instantaneously reproduce an image for viewing. Where the surveillance application demanded speed above all else, Itek’s sensor maintained a clear lead in its digital first pipeline. From the capture, the sensor readout could be stored inside a buffer until it would be rasterized and displayed on a CRT. If the analyst was sufficiently close to the optical system, they would be able to evaluate the image very shortly after capture should they desire, and if not, they would be able to store the image on tapes for later evaluation or display to other sections of the intelligence community.

Despite the TDI CCD sensors, however, the Itek sensor’s performance was mixed with regard to the resolution of image capture. The theoretical resolution of the optical system was much more limited than contemporary film emulsions and optical systems. The metric used to measure film resolution is called the Modulation Transfer Function (MTF) and is a means of translating information about both resolution and contrast into a single figure. The MTF is composed of two fundamental components: resolution and contrast modulation. The data provided by Itek isn’t offered as an MTF chart but does specify the resolution at a particular point along the chart. This system wasn’t nearly as highly resolving as the highest-resolving film of the period and the maximum MTF of the system was limited to a rather underwhelming 0.35. In contrast to even color

Ektachrome, the resolution was poor. The Ektachrome under production at the time was capable of an MTF of a high of 0.7. Modern digital solutions can reach MTFs of as high as 0.9 in optimal conditions.

The comparatively reduced resolution meant that either the optical system needed to be redeveloped or the sensor needed to be moved close to the subject. Here, the sensor’s weaknesses were overcome by the unique readout of the TDI sensor. Satellites, naturally, require very high altitudes to prevent rapid reentry, and moving any closer would require the use of surveillance planes. The massive size of the surveillance systems precluded that on the face, but even a smaller film system must still reckon with the fact that as a subject moves closer, its relatively movement is more apparent. In the case of slow, insensitive older film stocks, a plane would have introduced too much motion blur to be used practically. The TDI sensor, however, benefited from the motion of the subject relative to the capture device and meant that, for the first time a real aerial surveillance system could be digitally deployed.

Itek’s military-industrial and scientific imagining innovations were so bleeding edge during this period in history, and their electro-optical system was so sophisticated and uniquely capable that there weren’t yet military surveillance platforms that had been fabricated to deploy this technology. Itek intended their system for use in “low power, small-volume tactical platforms,” which today includes platforms like drones and small surveillance aircraft rather than larger and much more highly resolving platforms like satellites. Itek took advantage of the unique characteristics of electro-optical sensors to overcome the inherent limitations of film with respect to motion.

In retrospect, it’s easy to say the dominance of digital was inevitable, but even into the 2000s for non-critical commercial applications, film was considered to still offer some greater merit than digital. In the 80s, when Itek was actively developing this sensor, the inconvenience and inflexibility of film was sufficiently severe that even an inferior capture technology could win out in some domains based purely on the vastness of film’s practical limitations.

Notes

- When this paper was written in 1981, it was already possible to produce and display digital images and the process of switching from film for certain applications was already being discussed for limited deployments. The processing pipeline involved a lot of back and forth between digital and analog.

- The CCD being used was a line sensor, which at this point in time was the best option available

The lp/mm of this CCD was far far below that of contemporary film, but the delay of the development and processing pipeline made it unsuitable for some purposes - The image as it scans is stored in a buffer for later display on a CRT after it had been fully rasterized.

- The ability to display less data than was stored was apparently an advantage is some respect

- Itek was able to rapidly prototype because the system could be tested in a lab and adjusted on the fly, in a way which was less possible with film, given the chemical nature of the process.

References

Abrams, William J., and Frederick J. Gilligan. ‘Itek Model 2KL Sensor: The Mini-Electro-Optical Imaging System (Mini EOIS)’. San Diego. edited by Robert J. Bannach, 62–68. 25th Annual Technical Symposium. 1981.

Clevers, J. G. P. W., and H. T. C. Van Stokkom. ‘The Quantitative Evaluation of False Colour Photography with Application of a Red Filter’. International Journal of Remote Sensing 13, no. 9 (June 1992): 1709–33.

Fookes, P G, S G Dale, and J M Land. ‘Some Observations on a Comparative Aerial Photography Interpretation of a Landslipped Area’, n.d., 17.

Galiatsatos, Nikolaos. ‘The Shift from Film to Digital Product: Focus on CORONA Imagery’. Photogrammetrie – Fernerkundung – Geoinformation 2009, no. 3 (17 July 2009): 251–60.

Smith, D A, J J White, and W C Bradley. ‘A One-Inch High Resolution Buttable TDI Imaging BCCD’. Lexington, Masscussetts, n.d.

The images are sourced from the first citation: Abrams and Frederick 1981.