“The surprisingly affordable Canon AE-1: so advanced it’s simple.” that was the slogan behind an American commercial featuring the now well known Canon AE-1 SLR camera. It was such a hit because of the features that it offered, the automatic program exposure, and the variety of lenses available offered at a very affordable price point. When it launched in 1976, it cost $250–which was 40% more affordable than cameras from other companies at the time according to “Canon Historical Sketch: 1937-2007“.

While the Canon AE-1 was quite the successful product, it’s development was at one point halted. In 1975, a net loss from problems related to Canon’s calculators resulted in a major slowdown of its release. Yes; for those of you who don’t know, Canon makes calculators.

In April of 2016, the Canon AE-1 will be turning 40 years old. In those 40 years, it’s had quite a history.

The Build

According to Canon’s own user manual, the Canon AE-1 used a focal plane shutter and took 35mm film. The body was designed to use Canon FD lenses–which these days are in use amongst many mirrorless camera users after Canon moved over to the EOS lineup. The camera took ISO 25 to 3200 film (or you could shoot at a specific film and rate it another) and could shoot to 1/1000th or use the camera’s bulb mode. If you wanted to use the self timer, you’d have to wait 10 seconds until the camera took the photo. All of this was made possible by the power source: one 6v battery–which Canon rated to just under 1 year of use. If you used a flash, it could sync to 1/60th and with the 155A Speedlite the aperture and shutter were automatically set.

The Canon AE-1 was a camera that, contrary to popular belief, wasn’t made of metal. Instead, it had plastic designed to look and feel like metal. The Canon AE-1 introduced the use of plastic molding to make the manufacturing process simpler. What this also did was guarantee that the cameras could be lighter and less prone to breaking because of the flexible material. Indeed, the Canon AE-1 was rated at 590 grams without a lens. Just think about it: if a lens with a metal exterior took a dent vs a plastic exterior, the plastic would crack and be replaced–but the metal would need to be melted and fixed.

To that end though, the AE-1 still doesn’t feel like a cheaply made camera–and that was the object o much debate during it development. Back then, the sales department for Canon was vehemently against the introduction of plastic because they were afraid it would look cheap. So instead what happened was they tried to give the plastic a very metallic feel to it. This satisfied sales well enough.

Fast forward to today, and many companies who realize that today’s consumers really value retro ergonomics tend to use this manufacturing method for their camera exteriors while putting in measures to protect the internal parts such as an Aluminum or Magnesium Alloy Chassis.

Many photographers these days may argue that they want an all metal and well built camera–and we get this from older SLR cameras, Leica rangefinders and the entire retro styling trend that we value these days.

The move to metallic feeling plastics helped Canon manufacture loads of these cameras and also helped get it into the hands of so many people. Considering the earlier net loss mentioned earlier in this article, spending less and getting more would have been attractive to any company in the same situation.

The Canon AE-1’s CPU and Task X

One of the biggest things that made this camera so great was the CPU: which was designed to control pretty much all of the advanced automatic functions like exposure metering, the self-timer, power winder, automatic flash and even shooting photos.

Mr. Yoshiyuki Takishima of Canon lead a team of young engineers to begin tackling all the challenges involved with this CPU. Up to then, cameras with an AE functionally were only partially automated and with only some parts of the mechanism controlled electronically. This project to develop a fully automated camera was called the Task X project.

Eventually Canon teamed up with Texas Instruments for this project–you know, the calculator company. After a couple of months, they had a working CPU that could do pretty much everything they wanted. Because the camera incorporated electronics, the number of parts needed were less.

Major Parts

The camera was divided up into five major parts:

- Viewfinder

- shutter

- mirror

- AE mechanism

- Automatic aperture control mechanism

This made its assembly really simple and allowed Canon to produce loads of them. For example, it required really, really labor intensive precision adjustments to get 1/1000 of a second when it came to shutter speed. For other camera manufacturers, these cost cutting measures weren’t in place yet. However, the fact that Canon did this helped ensure that profits were larger and therefore helped to compensate for the previous fiscal year net loss report.

Sales and Success

“I love the AE-1, it was groundbreaking and ushered in a new generation of ‘pro-am’ photographers. They were a huge success for Canon.” says Bellamy Hunt: the Japan Camera Hunter about the AE-1. “Even now they are one of the go-to cameras for people starting their film journey. They are cheap, easily accessible and a fantastic way to get into shooting with film.” Bellamy added that the AE-1 is a very capable camera for not a lot of money and that everyone should shoot one at least once in their life.

The AE-1 was very popular in the US market because, well, the truth is that Americans are lazy. To this day I get emails from folks who want to push a button and get a great photo or pro quality. And for profits, it was very successful because of the then American mentality of making lots of money off of inexpensive unit sales. To a certain point, that philosophy still stands today.

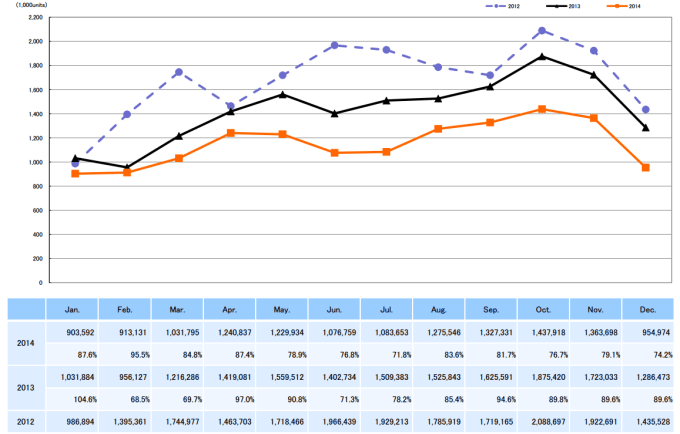

“Canon has never published any sales volume information about individual camera models, so I don’t have any official data to share.” says Canon USA’s Chuck Westfall in an email to the Phoblographer asking about sales. “But, unofficial estimates based on serial number range indicate that approximately 5.7 million units of the AE-1 were produced during its market life from 1976 to 1984. It’s worth remembering that according to CIPA, global SLR volume from all manufacturers during the film era peaked at roughly 7.5 million units in 1984, versus approximately 20 million DSLRs sold in 2012.”

While these numbers aren’t known, it’s an educated guess to say that more folks bought it when it was near the end of its life. With that said, there were probably massive discounts and rebates the same that there are today.

Either way, the Canon AE-1 is still a very well loved camera among many photographers who love shooting film. Walk around Brooklyn, and you’re bound to find at least one in the hands of someone any day of the week. Now that some of the cameras are nearing their 40th year, it’s quite amazing that they still work and function very well. Unfortunately, I can’t remember the last DSLR that anyone owned that lasted over 10 years.